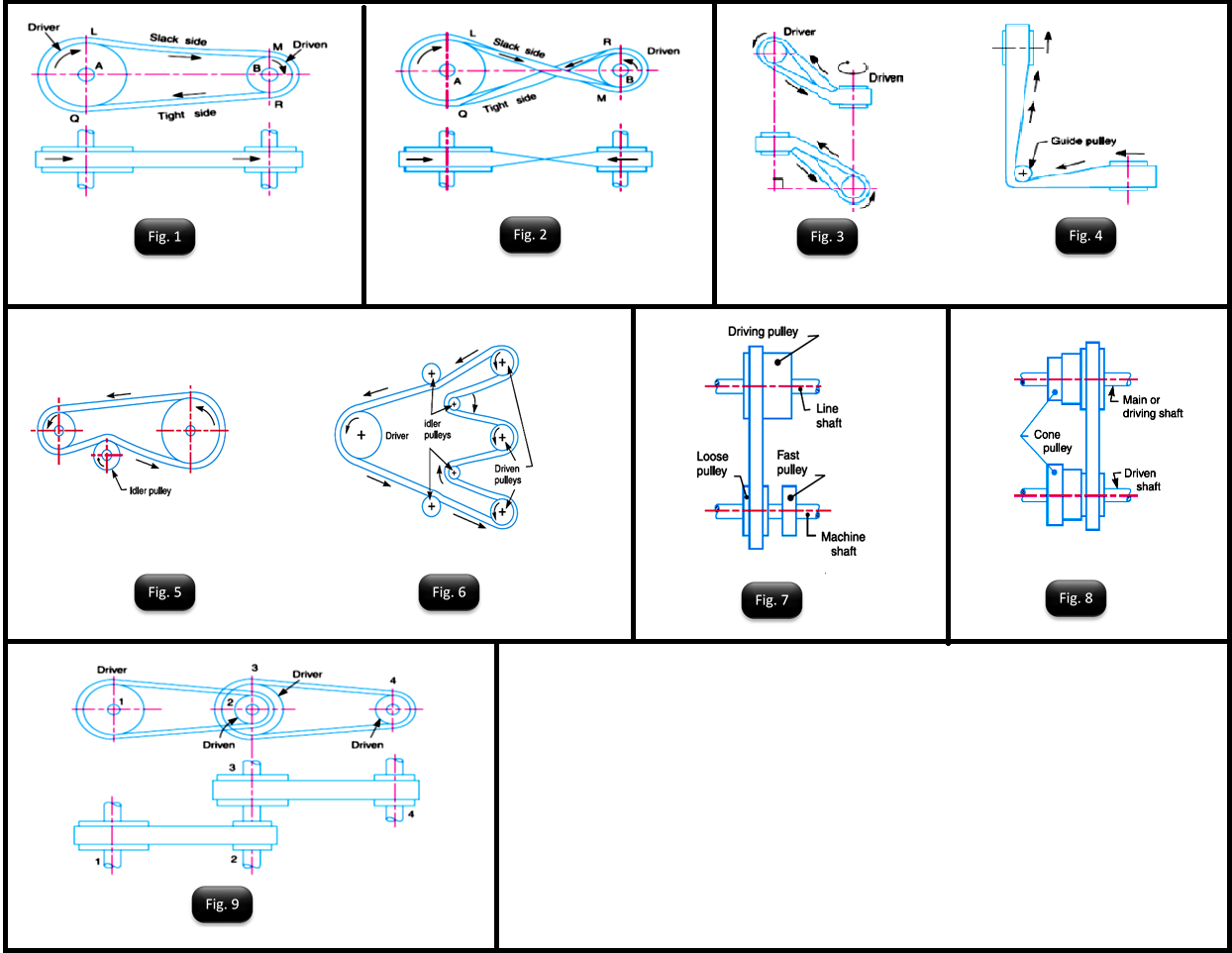

Describe briefly using neat diagrams the types of belt drives.

Open belt drive

As shown in Fig. 1, This type of belt drive is used to transmit power when two parallel shaft rotating is same direction. The portion of belt having high tension called tight side and portion of belt having less tension will be slack side.

Cross belt drive

As shown in Fig. 2, This drive transmits power when shafts are parallel but rotate in opposite direction. This type of drive should be used for large distance between two shafts and for lower speed.

Quarter turn belt drive

As shown in Fig. 3 & Fig. 4, The quarter turn belt drive is also known as right angle belt drive. It is used to transmit power between two shafts at right angle. When the reverse motion is desired this arrangement is not suitable.

Belt drive with Idler pulley

As shown in Fig. 5 & Fig. 6, After long time of running the length of belt may be increases, so angle of contact decreased. To increase it, it is required to increase tension. To increase tension in belt, Idler pulley is used.

Fast and Loose pulley drive

As shown in Fig. 7, This drive is used when it is need to start or stop driven shaft without stopping driver shaft. The pulley which is keyed to driven shaft is called fast pulley and a loose pulley runs freely over the machine shaft and not transmitting any power. When the driven shaft is required to be stopped, belt is pushed on loose pulley by sliding bar.

Stepped or Cone pulley drive

As shown in Fig. 8, A stepped or cone pulley drive used where different speed are required at driven shaft while driving shaft runs at constant speed.

Compound belt drive

As shown in Fig. 9, A compound belt drive is used when large speed ratio required and there is large center distance between two shafts. As shown in figure power is transmitted from pulley 1 to pulley 4 through intermediate pulley 2 and 3.